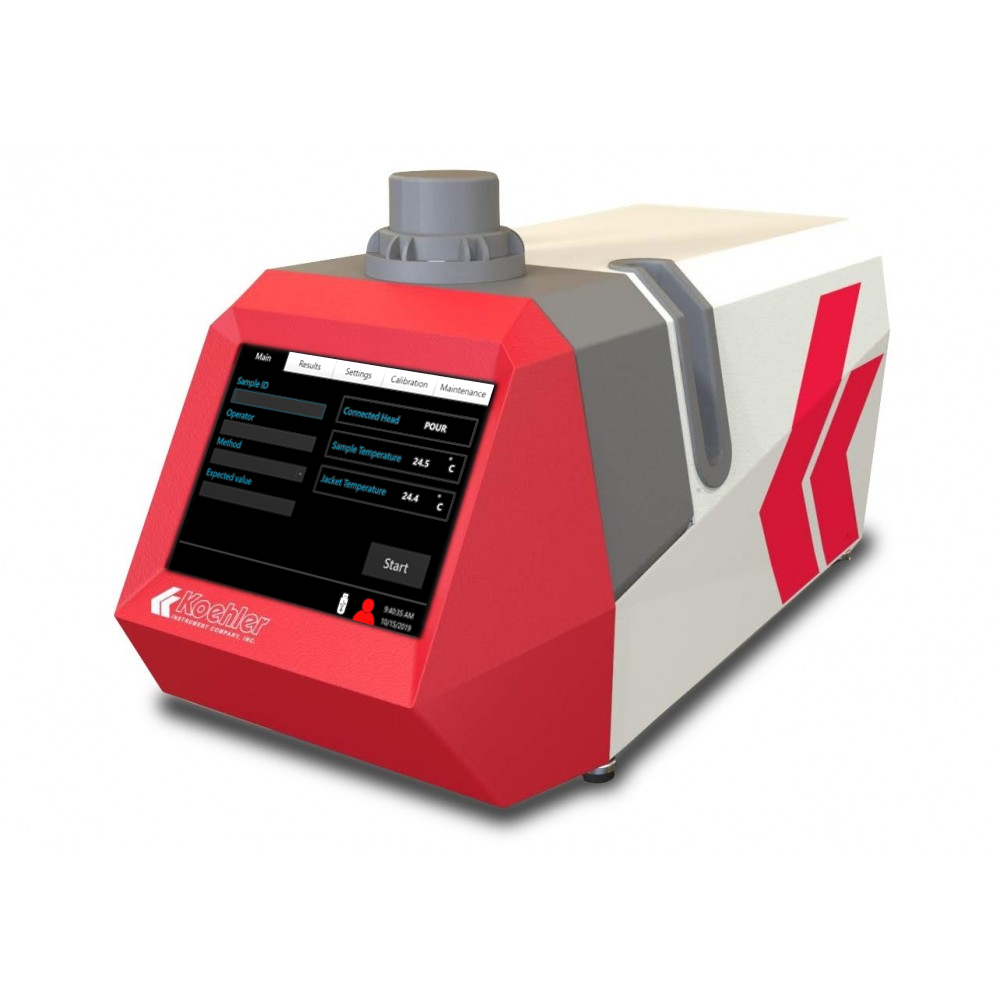

Automatic Cloud and Pour Point Analyzer

Cold flow properties, such as cloud point and pour point, indicate how petroleum products behave at low temperatures. The test specimen is cooled at a specified rate and measured periodically. The highest temperature at which a cloud is first detected at the bottom of the test jar is recorded as the cloud point. The lowest temperature at which movement of the specimen is detected is recorded as the pour point.

- Automatic determination of cloud point by Optical Detection

- Automatic determination of pour point via the Automatic Tilt Method

- Conforms to the specifications of ASTM D5771 and D5950

- Excellent correlation to ASTM D2500, D97, and related specifications

- Wireless Cloud Point Head

- Wireless Pour Point Head

- Integrated Cooling System

- Automatic Calibration by means of 10 point RTD Calibration, Sample Calibration, and Jacket Calibration

- 10.4-inch Integrated Color Touch Screen

- Standard test methods are pre-programmed or user-defined test programs can be created

- Clear graph of temperature vs. time for sample and bath temperatures

- Results can be easily searched, viewed on screen, printed, and exported to LIMS

- 4 USB interfaces

- Internet (Ethernet) Line

- 3 Point Electronics Calibration

- 10 Point RTD Offset Calibration

- Jacket Calibration

The Automatic Cloud and Pour Point Analyzer is a state of the art piece of equipment for measuring cloud point by optical detection and pour point with automatic tilt. The cloud point is an index of the lowest temperature of a petroleum product or a biodiesel fuel's utility for certain applications. Wax crystals of sufficient quantity can plug filters used in some fuel systems. The pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. Flow characteristics, such as pour point, can be critical for the correct operation of lubricating oil systems, fuel systems, and petroleum blending and pipeline operations.

Conforms to the specifications of: ASTM D5771, D5950

Excellent Correlation to: ASTM D97, D2500, D5853, D6074, D6158 ; ISO 3015, 3016; IP 15, 219; DIN 51597; FTM 791-201; NF T 60-105; JIS K2269

Detection:

Cloud Point: Optical Detection

Pour Point: Automatic Tilting

Cooling: Internal Cooling System

Temperature Range: -105 °C to +50 °C (-157 °F to +122 °F)

Temperature Accuracy: ± 0.1 °C

Tilt Interval: 1 °C or 3 °C as per test method (User defined for custom method 1 °C to 5 °C)

Interfaces: USB (4), Ethernet

Display:10.4" Color Touch Screen

Password Protection: Multi-level password capability

100-240 VAC 50/60Hz, Single Phase

WxDxH,in.(cm): 12.5 x 26.25 x 15.5 (31.75x66.68x39.37)

Net Weight: 90 lbs (41 kg)

Below are links to tutorial videos for this product