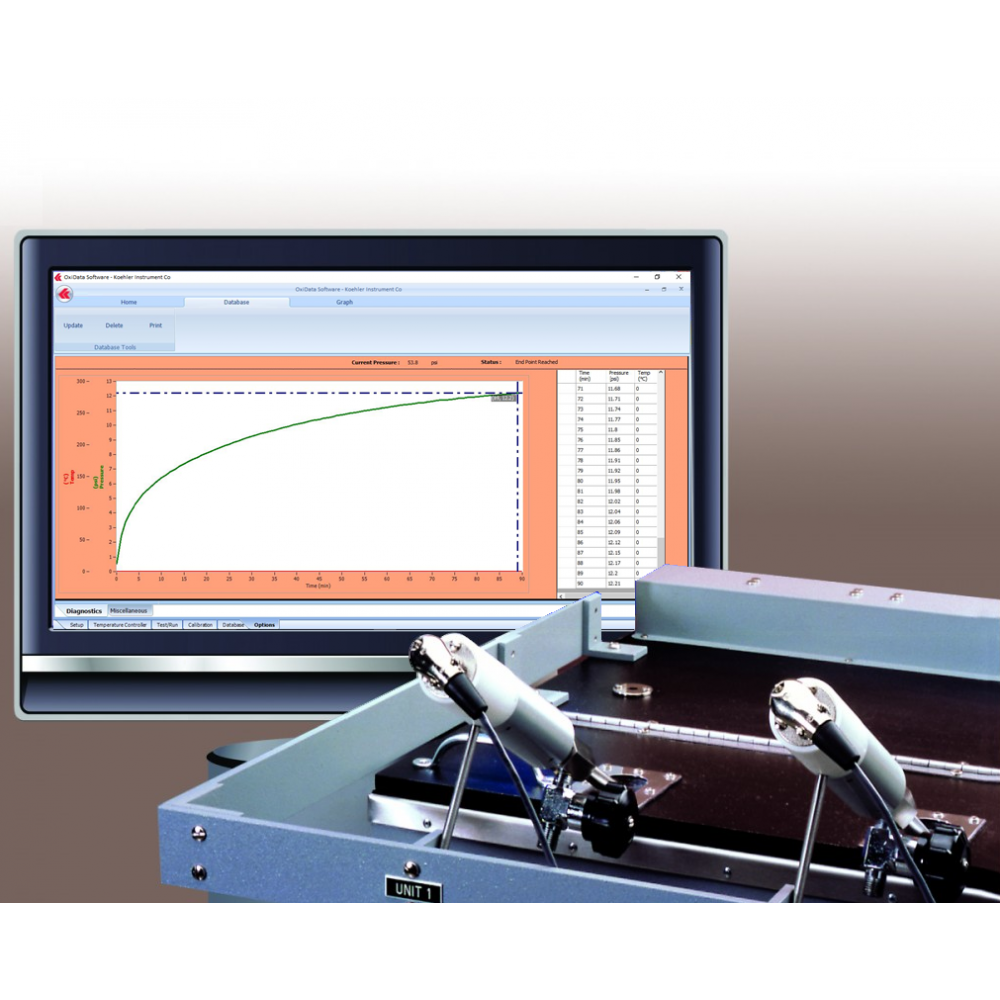

Oxidata® Pressure Measurement System for Lubricating Oils

Email Colleague

- On-line, real time monitoring of up to twelve samples simultaneously - results plot directly to the screen for instant monitoring or printout of results

- Menu options for RPVOT (RBOT) or TFOUT testing, as well as for other ASTM fuel and lubricant oxidation tests

- Programmable automatic end point detection with graphical and tabular representation

- Each channel can be configured and operated independently with different start/stop times and different ASTM test methods

- Zoom-in feature allows for magnification of any plot sector on any channel for a more detailed study

- Monitors and reports temperatures of as many as four baths simultaneously using accessory RTD’s, and calculates and displays average temperature for each bath. Exports data to spreadsheet programs such as Microsoft Excel

- Pressure calibration capability

- Data is saved directly to the hard drive during testing to prevent loss of valuable data

- Operates in Windows XP or higher

- Simple upgrade from existing Koehler data acquisition systems

- Computer Requirements

- Processor: Intel Core Duo

- Memory (RAM): 1GB or higher

- Windows XP or higher

- Disk Space: 10 MB free space (minimum)

- Communications Port: One USB port

- Other Software: Microsoft Excel

- Rotary transducers (connects directly to pressure vessel)

- Oxidata software

- USB Multiplexer

- RTD probe assembly (1)

- Connecting cables and hardware

Net Weight: 23 lbs (10.4 kg)

Shipping Weight: 28 lbs (12.7 kg)

Dimensions: 42x21x12 in. (106.7x53.3x30.5 cm)